Turning

Turning is a machining process used to produce cylindrical components by removing material from a rotating workpiece using cutting tools. The process involves the workpiece being rotated while a single-point cutting tool is traversed linearly across the surface of the rotating workpiece to remove material and create the desired shape. This process is commonly used to produce rotational parts such as shafts, rods, and discs.

What is Turning?

Turning is a machining process that shapes parts with specific features. It includes two main types of operations:

- Internal Operations:

- Drilling: Making holes inside a part.

- Boring: Enlarging holes to exact sizes.

- Reaming: Smoothing and refining holes for a perfect fit.

- Tapping: Creating internal threads for screws.

- External Operations:

- Facing: Cutting the ends of a part to make flat surfaces.

- Grooving: Making channels or notches on the surface.

- Cut-off: Separating parts from a larger piece.

- Thread Cutting: Forming external threads for easy fastening.

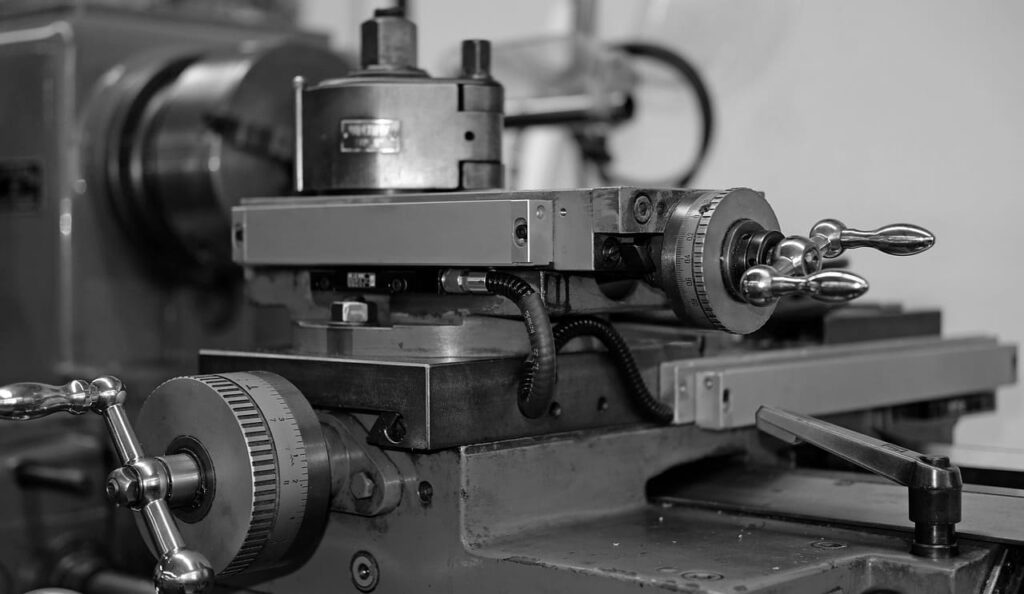

Our Turning Equipment: Key to Quality

The turning process relies on the right tools and machines. At SIMIC, we use a mix of advanced and traditional equipment:

- CNC Lathes:

- Our CNC (Computer Numerical Control) lathes automate the turning process, allowing for precise and repeatable machining. These machines can handle complex designs quickly and efficiently.

- Manual Lathes:

- We also use manual lathes for custom projects where hands-on skills are needed. These machines offer flexibility and control, perfect for one-off parts.

- High-Quality Tools:

- We invest in durable cutting tools that deliver excellent performance. Our toolkit includes various cutting bits and holders to ensure stability and precision during machining.

Why Choose Our Turning Services?

- Versatile Materials: We can work with metals, plastics, and even wood, so no matter your project, we have you covered.

- High Precision: Our CNC technology allows us to create parts with tight tolerances, essential for industries like automotive and electronics.

- Fast Turnaround: We streamline our processes to get your parts to you quickly without compromising quality.

- Great Surface Finish: Our turning process provides smooth and attractive finishes on all parts.

- Scalable Production: Whether you need a small quantity or a large batch, we can handle projects of all sizes efficiently.

Where Are Turned Parts Used?

Turned parts are crucial in many industries. Here are a few examples:

- Automotive: Custom shafts, gears, and fasteners that require precision for reliable performance.

- Aerospace: Components that must meet high standards for safety and accuracy.

- Industrial Equipment: Parts for machines that need to be durable and precise.

Contact SIMIC Manufacturing

When you choose SIMIC Manufacturing, you’re partnering with a reliable company dedicated to delivering high-quality turned parts that fit your exact specifications. Contact us today to learn more or request a quote!