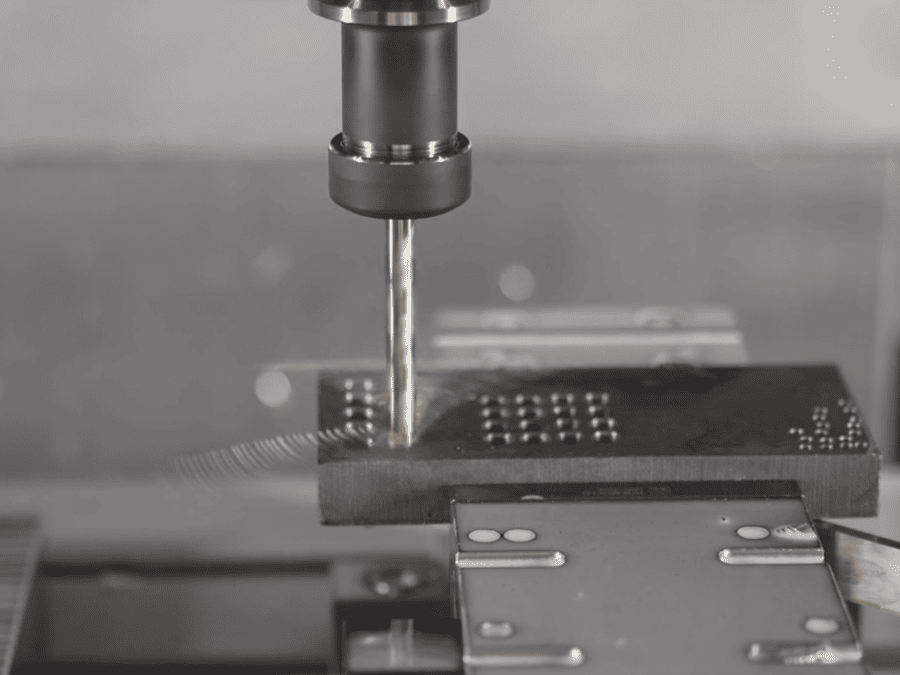

Drilling

Drilling, a foundational machining technique, entails the precise creation of holes in solid materials through the use of rotating drill bits. This critical operation is integral to industries such as manufacturing, construction, and mining, facilitating the creation of accurately positioned perforations essential for a multitude of applications. Employing axial force, the drill bit rotates at high speeds, systematically removing material to form holes of varying depths and dimensions.

Drilling Machine

Turning operations are performed on a lathe, which is a machine tool that rotates the workpiece on its axis while a cutting tool is applied to the workpiece to remove material. Lathes come in various types, including:

Drill Press: Often referred to as a bench drill, this stationary machine features a vertical spindle and worktable, serving as a staple in precision drilling operations across various materials.

Radial Drill: Renowned for its versatility, the radial arm drill press boasts a movable arm capable of adjusting to different positions along a radial column, making it ideal for drilling large or irregularly shaped workpieces.

CNC Drilling Machine: At the forefront of technological innovation, CNC drilling machines harness automation and computer control to execute intricate drilling tasks with unparalleled precision and efficiency, revolutionizing manufacturing processes.

Drilling Operations

Hole Drilling: Essential for creating cylindrical apertures of precise dimensions and depths, catering to diverse applications in manufacturing and construction.

Counterboring: Widely employed in heavy machinery manufacturing, counterboring involves enlarging the entrance of drilled holes to accommodate the heads of fasteners such as bolts or screws.

Countersinking: A critical operation in aerospace and automotive industries, countersinking creates conical recesses at hole entrances to facilitate flush fastening.

Spot Drilling: Preparatory in nature, spot drilling involves marking workpieces to guide subsequent drilling operations, ensuring accuracy and alignment.

Deep Hole Drilling: Integral to oil exploration and hydraulic machinery manufacturing, deep hole drilling enables the creation of boreholes with exceptional depth-to-diameter ratios, often exceeding 10:1.

Drilling Aplications

- Manufacturing: From precision parts in aerospace to intricate components in automotive, drilling plays a pivotal role in creating holes in diverse materials such as metal alloys, composites, and plastics.

Construction: In construction and infrastructure development, drilling is indispensable for creating holes in concrete, steel, and wood for electrical conduits, pipelines, and anchor bolts.

Mining: In mining and resource extraction, drilling operations facilitate the exploration and extraction of minerals and ores by creating boreholes for geological surveying and resource extraction.

Oil and Gas Exploration: Drilling serves as the cornerstone of oil and gas exploration, enabling the drilling of exploratory and production wells for the extraction of hydrocarbons from subterranean reservoirs.

Advantages of Drilling

Precision: Drilling machines boast exceptional precision and repeatability, ensuring the creation of holes with precise dimensions and alignment, critical for maintaining product integrity and performance.

Versatility: Versatile across industries, drilling is capable of creating holes in a wide range of materials, including hardened steel, titanium, and advanced alloys, catering to diverse application requirements.

Efficiency: Drilling stands as a paragon of efficiency, offering rapid hole creation capabilities, thereby enhancing productivity and throughput in manufacturing, construction, and resource extraction operations.

Automation: With the advent of CNC drilling machines, automation has revolutionized drilling processes, enabling the execution of complex drilling tasks with minimal human intervention, reducing labor costs and enhancing operational efficiency.

CONTACT SIMIC MANUFATURING

With our extensive experience and advanced machining capabilities, we provide reliable solutions for your manufacturing challenges. From prototyping to production, we are committed to delivering superior quality, efficiency, and cost-effectiveness in every project.

Feel free to contact us for a win-win future!