Simic Manufacturing Excellent Rail Components Supplier

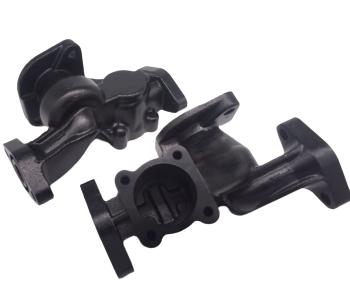

Premium Iron Casting Solutions for the Rail Industry

The rail industry relies on SIMIC Manufacturing for high-quality iron castings that ensure the performance and reliability of freight and locomotive engines. As a trusted supplier, we offer ductile iron casting solutions for critical components like braking systems.

Our partners help railroads transport heavier loads over longer distances with improved reliability and efficiency. Rail manufacturers depend on our expertise and cost-effective solutions to maintain a competitive edge.

SIMIC Manufacturing operates multiple facilities, producing variety types of ductile iron, gray iron castings. We also provide value-added services beyong castings, including machining, assembly, heat treating, and surface finishing, to streamline your supply chain and reduce time-to-market. With our robust machining capabilities, we can help you for parts of steel, stainless steel, aluminum, and brass machined from raw bar, plate, sheet tubing etc.

Trusted Components Selected by Leading Brands

Our Commitment to Your Success

At SIMIC Manufacturing, we prioritize your needs throughout the entire process, from concept to launch and beyond. Our core offerings include:

- Exceptional iron casting quality

- Competitive pricing strategies

- Consistent reliability

- Robust supply chain stability

We recognize the ongoing pressures you face—yearly cost reductions without compromising on quality or risking delivery delays. You can rely on us to support you in these challenges.

Our foundation is built on generations of foundry experience, where innovation and meticulous process control create a culture of success. Each step, from our in-house designed vertical molding machines to collaborative iron casting design, is crafted to enhance your operations.

At SIMIC Manufacturing, we collaborate closely with OEMs and Tier 1 suppliers to deliver customized solutions. This includes offering VA/VE support, exploring additive manufacturing options, and implementing innovative lightweighting strategies. We also assess the benefits of converting fabrications and weldments to iron castings, ensuring that your production processes are as efficient as possible.

Looking for a casting Quality improvement, lightweighting solution, design support, or cost reduction?