Copper: Precision Machining for Versatile Applications

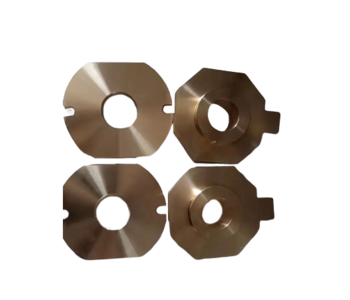

At SIMIC Manufacturing, we specialize in delivering high-quality brass components designed to meet the diverse needs of our clients. While we do not offer brass casting services, we leverage our extensive machining capabilities to produce brass parts from rods, sheets, and other forms. Our advanced machining processes ensure precision, durability, and consistency in every part we fabricate.

Why Choose Brass?

Brass is a versatile alloy primarily composed of copper and zinc, known for its excellent machinability, corrosion resistance, and appealing golden appearance. These characteristics make it an ideal choice for a wide range of applications, from electrical components to decorative items. Brass also has good thermal and electrical conductivity, making it highly suitable for industries such as electronics, plumbing, and automotive.

Key Properties of Brass:

- Corrosion Resistance: Brass is highly resistant to corrosion, especially in moist environments, making it a durable material for both indoor and outdoor applications.

- Machinability: Brass is easy to machine, with a smooth surface finish, allowing for complex shapes and fine details to be produced with high precision.

- Electrical Conductivity: The alloy’s copper content provides good electrical conductivity, making brass an excellent choice for electrical connectors and components.

- Aesthetic Appeal: Brass is often used in decorative items due to its bright, yellowish color, providing a sophisticated and elegant look.

Brass Grades Available at SIMIC

At SIMIC, we offer brass alloys in various grades, allowing us to meet a wide range of industrial requirements. Below is an overview of the grades we work with, based on international standards:

| Standard | Grades Available |

|---|---|

| China (GB/T 5231) | H62, H65, H68, H70 |

| United States (ASTM B16) | C26000 (Brass 260), C27000 (Brass 270) |

| Europe (EN 12164) | CuZn37, CuZn39Pb3 |

| Japan (JIS H3250) | C2600, C2700 |

Standards Comparison

| Standard | China (GB/T 5231) | United States (ASTM B16) | Europe (EN 12164) | Japan (JIS H3250) |

|---|---|---|---|---|

| Brass 260 | H62 | C26000 | CuZn37 | C2600 |

| Brass 270 | H65 | C27000 | CuZn39Pb3 | C2700 |

Applications of Brass

Brass is used in a variety of industries for both functional and decorative purposes. Some of its common applications include:

- Electrical Components: Brass is commonly used for connectors, terminals, and switches due to its excellent electrical conductivity and durability.

- Plumbing Fittings: Brass’s resistance to corrosion makes it ideal for water and gas fittings, faucets, and valves.

- Automotive Parts: Brass is used in making automotive connectors, radiators, and other components that require strength and resistance to corrosion.

- Decorative Items: Its golden appearance and ease of machining make brass an excellent material for creating decorative items such as jewelry, hardware, and accessories.

Our Fabrication Process

SIMIC Manufacturing employs advanced machining techniques such as turning, milling, and grinding to create precision brass parts. Our team utilizes the latest CNC machinery to ensure high-quality finishes and tight tolerances, whether you require small intricate components or large, more robust parts.

We focus on delivering brass components that meet both functional and aesthetic standards. With strict quality control and continuous improvements in our manufacturing processes, we guarantee that each part will perform well in its intended application.

Contact SIMIC Manufacturing

At SIMIC, we combine years of industry expertise with cutting-edge technology to offer high-quality brass components. Whether you need standard or custom brass parts, our machining capabilities and extensive knowledge allow us to provide solutions that meet your exact requirements.

Contact SIMIC Manufacturing today to learn more about our brass fabrication services and how we can support your project needs.