Gray Iron: A Time-Tested Material Choice

At SIMIC Manufacturing, we specialize in producing high-quality gray iron components that meet diverse industrial requirements. Gray iron, a mixture of iron, carbon, and silicon, is known for its distinctive color and the graphite flakes that contribute to its unique properties.

About Gray Cast Iron

Gray cast iron is characterized by its high carbon content (typically 2.5–4%) and silicon content (1–3%), with iron making up about 95% of the alloy. The presence of graphite flakes—up to 6–10% of the total volume—affects the material’s strength and brittleness. While these flakes do not add strength, they help absorb vibrations, making gray iron an excellent choice for applications requiring damping properties.

The properties of gray iron can be tailored by adjusting the ratios of its components and controlling the cooling process. For example, increasing the silicon content stabilizes the graphite, while slower cooling times may enhance the amount of graphite in the final product.

Historically, gray iron was first produced in China over 2,000 years ago for weapons and everyday tools, gaining popularity in the West during the mid-15th century.

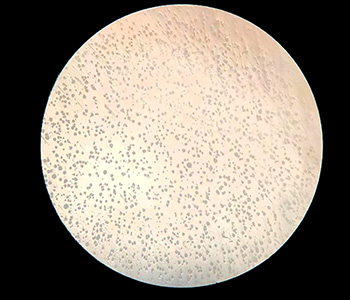

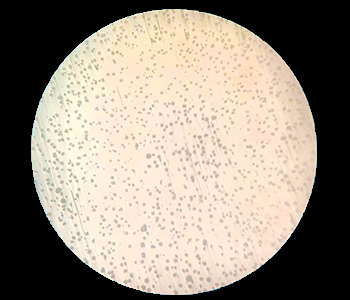

Microstructure of Gray Iron

Material Grades Available at SIMIC

| GB/T 9439 | Tensile Strength (MPa) | Hardness Range (HB) |

|---|---|---|

| HT150 | ≥ 150 | 90-150 |

| HT200 | ≥ 200 | 140-180 |

| HT250 | ≥ 250 | 170-230 |

| HT300 | ≥ 300 | 200-280 |

Standards Comparison

| GB/T 9439 | ASTM A48 | EN 1563 | JIS G 5502 |

|---|---|---|---|

| HT150 | Class 20 | GJL 150 | FC 150 |

| HT200 | Class 25 | GJL 200 | FC 200 |

| HT250 | Class 30 | GJL 250 | FC 250 |

| HT300 | Class 35 | GJL 300 | FC 300 |

Properties of Gray Iron

- Cost-Effectiveness: Gray iron is one of the most economical types of cast iron.

- Ductility and Strength: While its tensile strength may be limited, gray iron exhibits good compressive strength and impact resistance.

- Thermal Conductivity: Gray iron is an excellent conductor of heat, allowing for even heat distribution—ideal for cooking and engine components.

- Vibration Damping: The graphite flakes help dampen vibrations, making it suitable for bases of machinery and various automotive components.

Advantages of Gray Iron Castings

Gray iron castings offer numerous advantages, including:

- Affordability: It is cheaper compared to other cast iron types, making it a practical choice for many applications.

- Vibration Absorption: Its ability to dampen vibrations is critical for applications like manholes, gears, and disc brakes.

- Thermal Cycling Resistance: Gray iron can withstand thermal cycling, making it suitable for high-temperature applications such as stoves and car engines.

- Machinability: The graphite structures act as a lubricant during machining, allowing for easier cutting and chip-breaking.

Applications for Gray Iron

Thanks to its many benefits and low cost, gray iron is widely used in:

- Weights and Counterweights: Its compressive strength makes it ideal for manufacturing heavy components.

- Automotive Parts: Used in suspension systems and brake components, gray iron effectively absorbs vibrations and withstands thermal cycling.

- Household Items: Gray iron is commonly used in cookware and appliances due to its excellent heat conductivity.

Contact SIMIC Manufacturing

We are committed to providing our customers with ductile iron components that meet their specific needs. Our experienced engineering team collaborates closely with clients to deliver tailored solutions that enhance product performance and reliability.

For further information about our gray iron components and services, please contact us through our website or submit a request for a quote. Our team is here to assist you in finding the right solutions for your needs.