Ductile Iron: A Superior Material Choice

At SIMIC Manufacturing, we specialize in producing high-quality ductile iron components that meet the rigorous demands of various industries. Ductile iron, also known as nodular cast iron, offers numerous advantages over traditional cast iron materials, making it an ideal choice for applications requiring enhanced strength, ductility, and wear resistance.

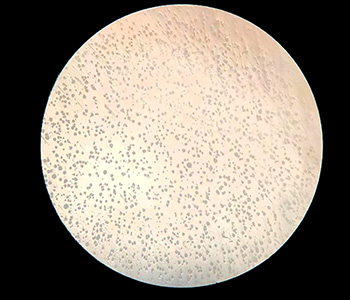

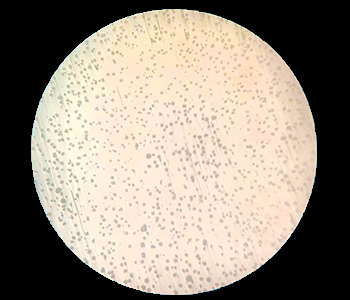

Microstructure of Ductile Iron

Material Grades Available at SIMIC

| GB/T 1348 | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness Range (HB) |

|---|---|---|---|---|

| QT400-15 | ≥ 400 | ≥ 240 | ≥ 15 | 140-210 |

| QT450-12 | ≥ 450 | ≥ 300 | ≥ 12 | 170-230 |

| QT500-7 | ≥ 500 | ≥ 350 | ≥ 7 | 170-230 |

| QT600-3 | ≥ 600 | ≥ 450 | ≥ 3 | 200-250 |

| QT700-2 | ≥ 700 | ≥ 550 | ≥ 2 | 220-290 |

| QT800-2 | ≥ 800 | ≥ 650 | ≥ 2 | 250-300 |

Standards Comparison

| GB/T 1348 | ASTM A536 | EN 1561 | JIS G 5500 |

|---|---|---|---|

| QT400-15 | 60-40-18 | EN GJS 400-15 | FCD 400 |

| QT450-10 | 65-45-12 | EN GJS 450-10 | FCD 450 |

| QT500-7 | 70-50-05 | EN GJS 500-7 | FCD 500 |

| QT600-3 | 80-55-06 | EN GJS 600-3 | FCD 600 |

| QT700-2 | 85-65-03 | EN GJS 700-2 | FCD 700 |

Key Properties of Ductile Iron

- exceptional Strength: Ductile iron exhibits superior tensile strength compared to conventional gray iron, enabling it to withstand heavy loads and stress without failure.

- Enhanced Ductility: This material is designed to deform under stress, which helps prevent catastrophic failure. Its ability to absorb energy makes it suitable for dynamic applications.

- Excellent Wear Resistance: Ductile iron’s surface properties provide outstanding wear resistance, making it ideal for components that face abrasive conditions.

- Corrosion Resistance: With the right coatings and treatments, ductile iron can resist corrosion, extending the life of components in harsh environments.

- Versatile Applications: Ductile iron is used in a wide range of applications, from automotive parts to heavy machinery components, owing to its adaptability and performance.

Manufacturing Process

At SIMIC Manufacturing, our ductile iron components are produced using state-of-the-art casting techniques, ensuring precision and consistency in every part. Our rigorous quality control measures include:

- Material Selection: We source high-quality raw materials to ensure the best properties in our final products.

- Casting Techniques: Utilizing advanced casting methods, we achieve complex shapes and dimensions with high accuracy.

- Testing and Inspection: Each component undergoes stringent testing to verify its mechanical properties, ensuring compliance with industry standards.

Contact SIMIC Manufacturing

We are committed to providing our customers with ductile iron components that meet their specific needs. Our experienced engineering team collaborates closely with clients to deliver tailored solutions that enhance product performance and reliability.

Choosing ductile iron for your projects means opting for a material that combines strength, flexibility, and durability. At SIMIC Manufacturing, we take pride in our ability to produce exceptional ductile iron components that support your operational goals. Contact us today to learn more about our capabilities and how we can assist you with your next project.